In this method, the d.c. machine is loaded and output and input are measured to find the efficiency. For this purpose, two simple methods can be used.

Net pull on the rope = (W - S) kg-Wt = (W - S)*9.81 newtons

If r is the radius of the pulley in metres, then the shaft torque Tsh developed by

the motor is

If the speed of the pulley is N r.p.m., then,

Let V = Supply voltage in volts

I = Current taken by the motor in amperes

Input to motor = V I watts

(ii) In another method, the motor drives a calibrated generator i.e. one whose efficiency is known at all loads. The output of the generator is measured with the help of an ammeter and voltmeter.

Input to motor = VI

Thus efficiency of the motor can be determined.

Because of several disadvantages (See Sec. 6.1), direct loading method is used

only for determining the efficiency of small machines.

Tags:theory of brake test on dc shunt motor,brake test on dc compound motor,break test on dc shunt motor,break test on dc shunt motor theory,dc motor evaluation,brake test on dc shunt motor viva

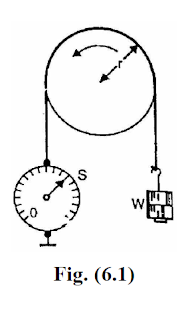

Brake test on dc machine:-

In this method, a brake is applied to a water-cooled pulley mounted on the motor shaft as shown in Fig.(6.1). One end of the rope is fixed to the floor via a spring balance S and a known mass is suspended at the other end. If the spring balance reading is S kg-Wt and the suspended mass has a weight of W kg-Wt,then,If r is the radius of the pulley in metres, then the shaft torque Tsh developed by

the motor is

Tsh = (W - S)*9.81*r N - m

Let V = Supply voltage in volts

I = Current taken by the motor in amperes

Input to motor = V I watts

(ii) In another method, the motor drives a calibrated generator i.e. one whose efficiency is known at all loads. The output of the generator is measured with the help of an ammeter and voltmeter.

Output of motor =Generator output/Generator efficiency.

Let V = Supply voltage is volts

I = Current taken by the motor is amperesInput to motor = VI

Thus efficiency of the motor can be determined.

Because of several disadvantages (See Sec. 6.1), direct loading method is used

only for determining the efficiency of small machines.

Tags:theory of brake test on dc shunt motor,brake test on dc compound motor,break test on dc shunt motor,break test on dc shunt motor theory,dc motor evaluation,brake test on dc shunt motor viva